Gold is one of the first metals that humans have become familiar with and is found in nature mainly in the form of flakes. Its properties and appearance make gold an ideal material for jewellery - it is shiny, soft and highly ductile. Pure gold is too soft to be used in jewellery, so it is alloyed with other metals to achieve the desired workability, hardness and colour.

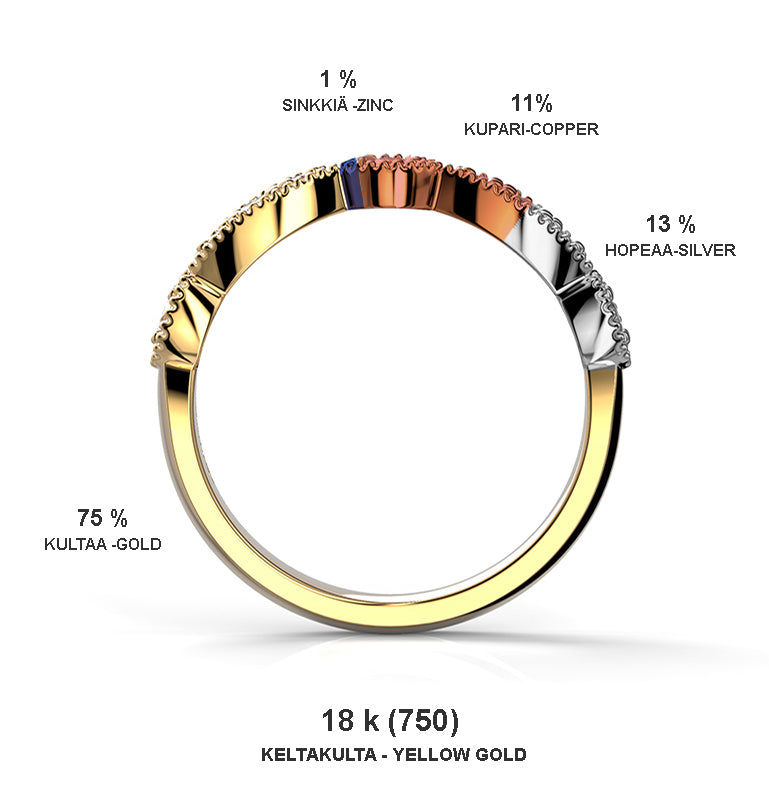

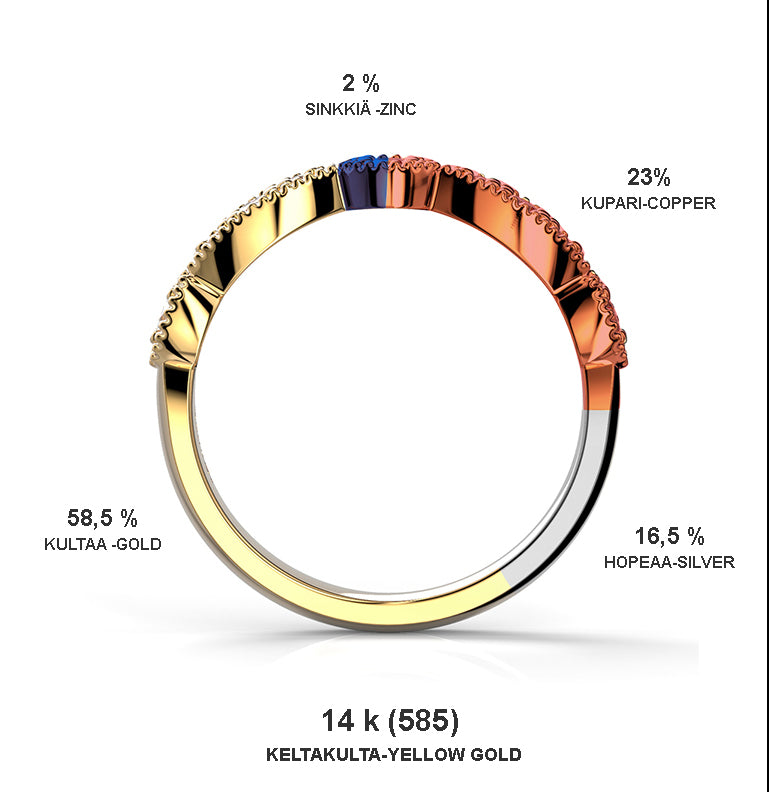

Yellow gold is obtained by adding silver and copper to gold. Red gold is obtained by increasing the amount of copper. White gold is obtained by adding palladium to gold. Zinc is used to a small extent in all alloys to improve casting and machining properties.

In Finland, the gold content of gold alloys is stamped in parts per million, but is often expressed colloquially in carats. Per mil or parts per thousand indicate the amount of precious metal that must be present in the product. One carat, on the other hand, means 1/24th part. The most typical gold alloys used in jewellery are 14 carats, or 585 parts per thousand, and 18 carats, or 750 parts per thousand.

Yellow gold

Festive diamond jewellery uses the so-called European shade of yellow gold, which is a brighter yellow than the reddish Finland blend commonly used in Finland. It is also possible to order diamond jewellery made from the reddish Finland alloy, but the default setting when ordering online is a more yellowish alloy.

White gold

White gold contains just as much fine yellow gold as yellow and red gold alloys of other colours with the same concentration. White gold gets its pale colour from the palladium metal alloyed with it. Palladium is heavier and more expensive than other alloying metals. For this reason, white gold products are slightly more expensive than yellow and red gold products.

White gold is surface-treated with rhodium, a metal of the platinum group. This is called rhodium plating. Rhodium plating gives white gold a pure white surface, whereas white gold itself has a greyer colour. The rhodium plating will wear off over time and may need to be replaced when the ring starts to become scratched and greyish in colour.

Red gold

Red or rose gold is obtained by adding copper to the gold alloy to give it a red hue. Red gold has really taken off in the market in recent years and is very trendy at the moment.

Recycled gold

The gold alloy we use is all certified recycled gold supplied by K.A. Rasmussen. K.A. Rasmussen guarantees over 99% recycling of the alloy, but in practice under normal conditions the recycling rate is 100%. We also try to buy as much scrap gold as possible from our customers for recycling. Thanks to recycling, the story of Grandma's old sturdy engagement ring can be continued in up to five new elegant rings.

Scrap gold is cleaned

Large quantities of so-called scrap gold, such as old jewellery, are melted down and purified through mechanical, chemical and electrolytic processes into pure precious metals that can be reused again and again. We are always able to use the best and highest quality purification processes on the Nordic market.

Gold is realloyed

Gold, which is 99.99% pure, is alloyed with other alloying metals such as silver, copper, zinc and palladium (in the case of white gold). Once the correct alloying ratios have been accurately calculated, the metals are melted together on a hot flame to form a single alloy.

The molten alloy is poured into the mould.

The molten alloy, which is well above 1000°C, is cast into the desired mould to form a goldsmith's blank for jewellery making. The blank from the mould can be a bar, a plate or a casting that follows the shape of the jewellery, which is used in particular to produce identical jewellery in series.

Gold alloys

Below are the alloy ratios of 14k and 18k yellow gold in percentages.